SAP Industry 4.0 Solution

Industry 4.0 – Intelligence Manufactory SAP Solution

Manufacturing companies are challenged to increase productivity while producing individualized products with high quality in an environment of constantly changing and varying customer demand. Many companies recognize Industry 4.0 as strategic priority to turn these challenges into opportunities. Industry 4.0, or the Industrial Internet of Things (IIoT), is about industrial transformation using new digital technology that makes it possible to gather and analyze data across machines and business systems, enabling faster, more flexible, and more efficient processes to produce higher quality individualized goods at lower cost. Technology innovations like the IoT, edge and cloud computing, Big Data lakes, artificial intelligence, sensors, autonomous systems, and robots are drivers for the change. Creating value from Industry 4.0 requires an industry-specific approach as business goals and challenges vary by industry – and even by company. Industry 4.0 will radically change production across discrete and process industries. Production equipment will become highly autonomous. It is about industrial transformation using new digital technology that makes it possible to gather and analyze data across machines and business systems – enabling faster, more flexible, and more efficient processes to produce higher-quality, individualized goods at reduced costs.

- Focus on customers: Put your customers’ input, preferences, and expectations for products and services at the center of all you do.

- Reinvent production: Use intelligent assets and processes that dynamically adapt to changing priorities and deliver customization at scale.

- Connect the entire company:Orchestrate sales, service, and logistics processes along with production operations to transform how your employees work.

Personalized brand promises will be integrated into customer experiences

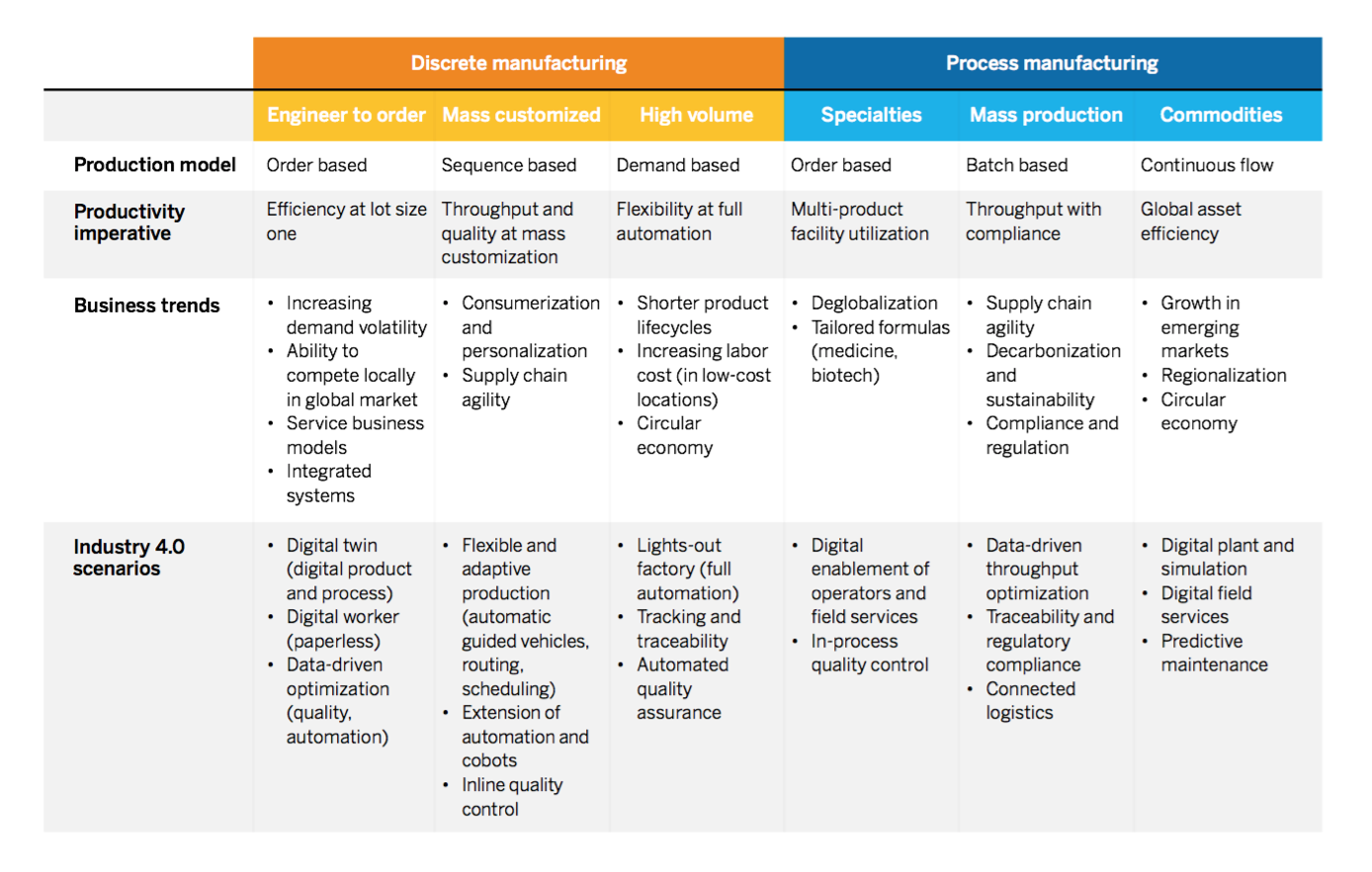

By 2025, we believe that high tech companies will rely on platforms and subscription-based services for monetizing intellectual property to provide the efficient, reliable products and consumer-grade experiences customers expect. APPROACH FOR INDUSTRY 4.0 Creating value from Industry 4.0 requires an industry specific approach as business goals and challenges vary by industry and even by company. There is no one-size-fits-all Industry 4.0 approach. Three distinctive clusters can be identified for discrete manufacturing based on the average lot size and the number of variants per factory:

- Engineer-to-order production models, found in industries like shipbuilding, high-end machinery, and aerospace, executing on small or individual production orders, strive for high efficiency in manufacturing down to lot size 1.

- Mass-customized production, typically in automotive, agriculture equipment, and industrial components, aims at maintaining high-sequence throughput and consistent quality despite increased product variances.

- In high-volume production, such as consumer electronics, commercial equipment, or semiconductor chips, full automation (lights-out production) drives further productivity increase while changing product mixes require higher flexibility or production line adaptation.

In process manufacturing, lot size becomes batch size while variants per factory translates into the number of different formulas or recipes per plant.

- For order-based specialty production, multi-product facility utilization becomes most important. New technologies allow tailoring

of products to individual needs, but require efficient use of production equipment.

- In mass-production, batch-oriented industries, such as fine chemicals, paper, metals, construction materials, food, or pharma, high throughput objectives are increasingly combined with compliance, regulation, and traceability requirements.

- For commodities, such as petrochemicals, bulk chemicals, and ore in mining, asset efficiency of continuous flow production on a global level drives further optimization.

*Figure: examples of Industry 4.0 scenarios that have emerged to deliver short-term business value across discrete and process industries.

Industry 4.0 Scenario Examples Across Industry Clusters

THEMES AS DRIVERS FOR INDUSTRY 4.0

THEMES AS DRIVERS FOR INDUSTRY 4.0

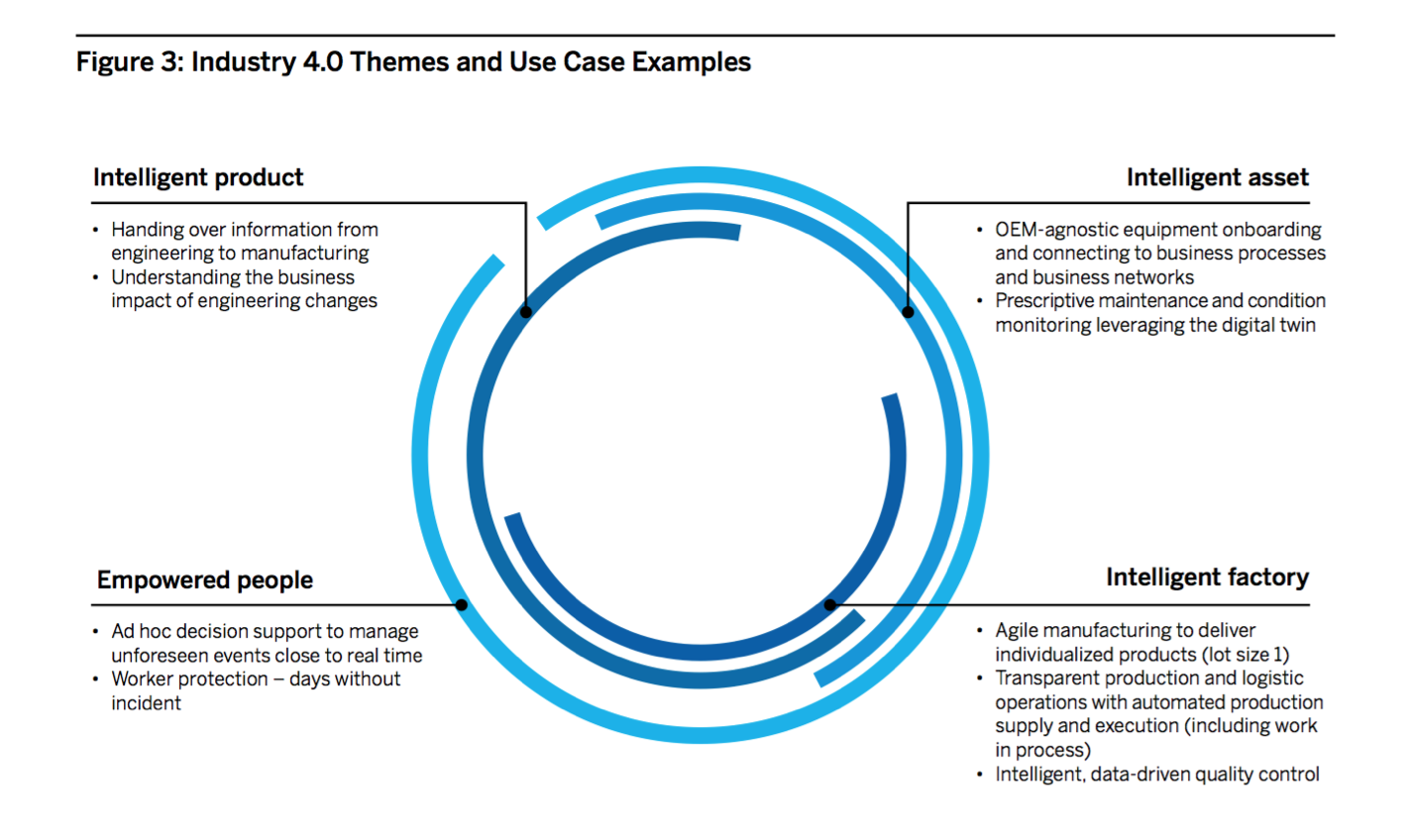

SAP believes that Industry 4.0 is driven by four themes providing distinct value to the business. Intelligent products are built and configured to meet exactly what customers need. Intelligent assets are linked to all processes and are dynamically maintained. Intelligent factories use data and intelligence to run as autonomously as possible and deliver customized products at scale. Empowered people are equipped with all the tools and information they need to do their best work.

Industry 4.0 Themes and Use Case Examples

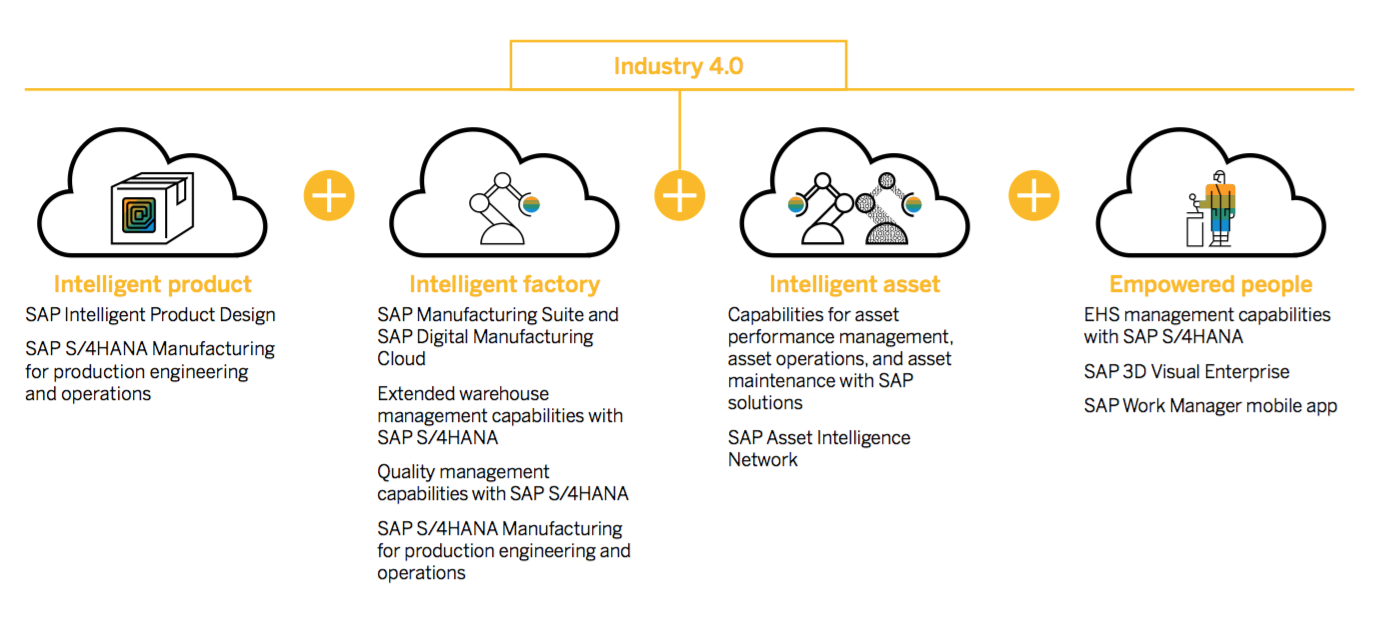

OVERVIEW OF SAP SOLUTIONS SAP has the broad solution portfolio to unlock the value of Industry 4.0, combining the power of intelligent manufacturing in factories and plants with end-to-end business process execution across the supply chain. SAP’s Industry 4.0 approach combines three business priorities to one leading strategy:

OVERVIEW OF SAP SOLUTIONS SAP has the broad solution portfolio to unlock the value of Industry 4.0, combining the power of intelligent manufacturing in factories and plants with end-to-end business process execution across the supply chain. SAP’s Industry 4.0 approach combines three business priorities to one leading strategy:

- Focus on customers, so their input and preferences are the source of all you do

- Reinvent production, using intelligent assets and processes that dynamically adapt to changing priorities and deliver customization

at scale

- Connect the entire company, orchestrating, sales, service, and logistics with production to transform how you work

Products & Technology Supporting Industry 4.0 Themes

About MTC & Versino

MTC & Versino GmbH, located in Munich, Germany, is the first Sino-German joint venture of SAP consulting company. It is co-established by MTC and Versino AG, aiming to provide professional digital transformation consulting and SAP services to Chinese and German multinational enterprises.

- Data Privacy |

- Legal Note |

- Site Map |